Safety Leadership

Safety Leadership

Course Name

Machinery Series - Introduction to safeguarding and safety related controlsCourse Description

A control system or device is deemed to be safety related if it provides functions which significantly reduce the riskof a hazard, and in combination with other risk reduction measures, reduces the overall risk to a tolerable level, or

if it is required to function to maintain or achieve a safe state for the equipment under control (EUC).

These functions are known as the safety functions of the system or device and are the ability to prevent initiation of a hazard or detect the onset of a hazard, and to take

the necessary actions to terminate the hazardous event, achieve a safe state, or mitigate the consequences of a hazard.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8

Course Name

Machinery Series - Introduction to safeguarding and safety related controlsCourse Description

A control system or device is deemed to be safety related if it provides functions which significantly reduce the riskof a hazard, and in combination with other risk reduction measures, reduces the overall risk to a tolerable level, or

if it is required to function to maintain or achieve a safe state for the equipment under control (EUC).

These functions are known as the safety functions of the system or device and are the ability to prevent initiation of a hazard or detect the onset of a hazard, and to take

the necessary actions to terminate the hazardous event, achieve a safe state, or mitigate the consequences of a hazard.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series Safety ControlsPrerequisite Name:

Prerequisite Short Code:

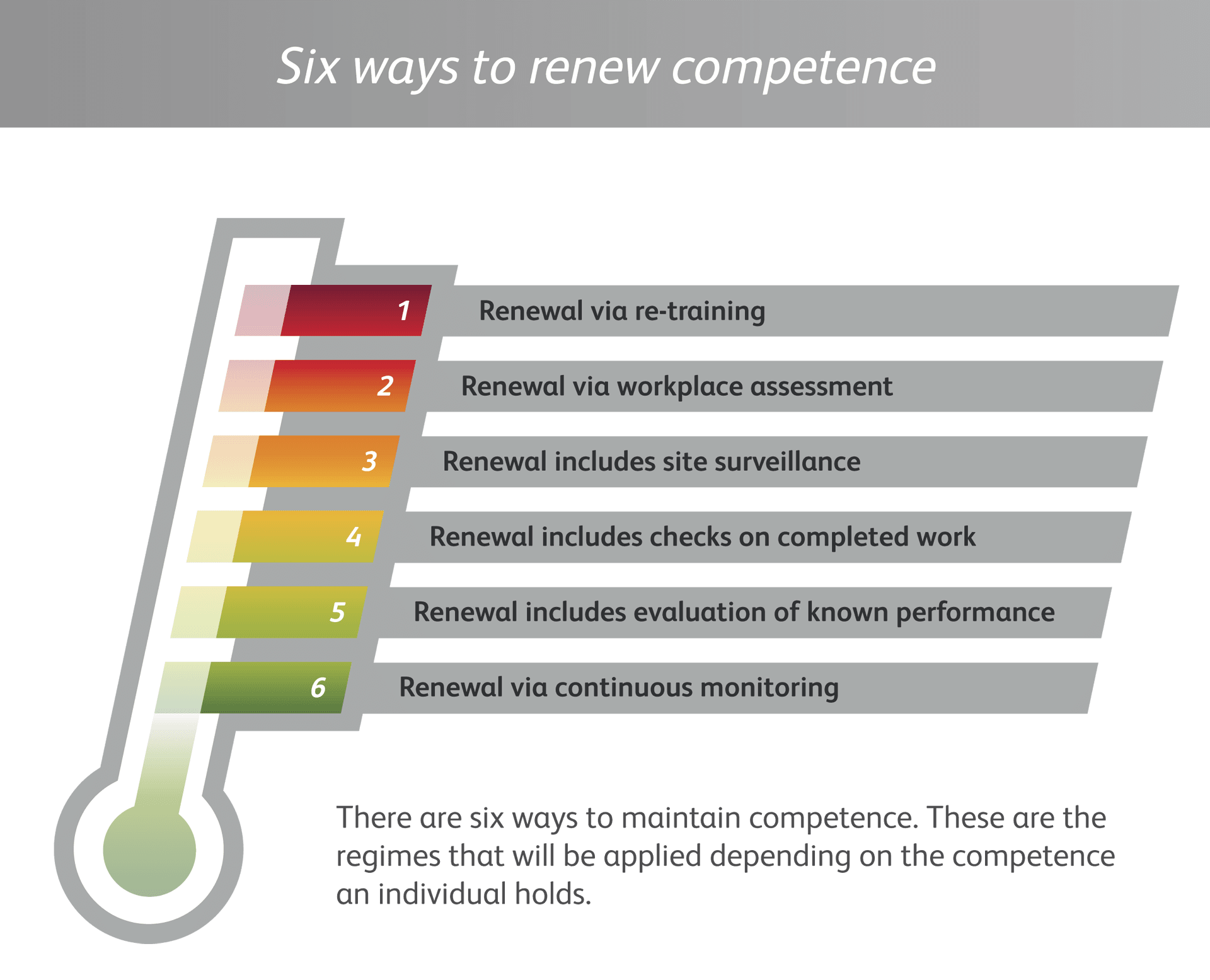

Skills Assessment Scheme Regime:

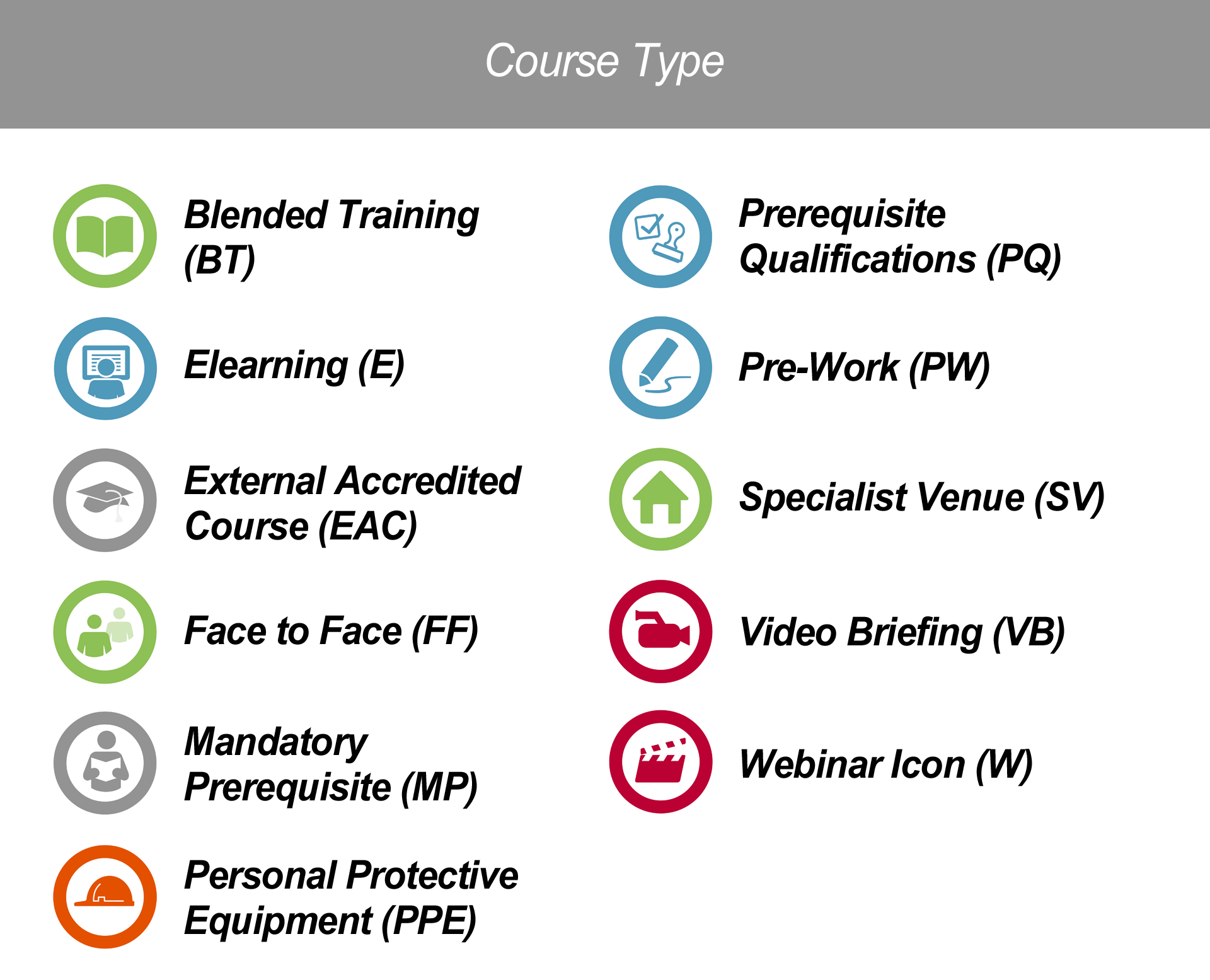

Course Type:

Course Name

Machinery Series - Machinery Machinery DirectiveCourse Description

This course gives delegates a thorough understanding of this legislation, as revised, as well as the key currentEuropean and International safety standards that support the Regulations. Delegates are shown how to build a

technical file and can practice assessing conformity to the essential health and safety requirements. The purpose

and content of a declaration of conformity and incorporation are explained along with when to use which. The role

and process of risk assessment are explained.

The design, supply and incorporation of machinery into assemblies within the European Economic area is governed by the European Machinery Directive that was significantly amended in 2006. In the UK this directive has been transposed into the Supply of Machinery (Safety)

Regulations that came into force at the end of December 2009.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8

Course Name

Machinery Series - Machinery Machinery DirectiveCourse Description

This course gives delegates a thorough understanding of this legislation, as revised, as well as the key currentEuropean and International safety standards that support the Regulations. Delegates are shown how to build a

technical file and can practice assessing conformity to the essential health and safety requirements. The purpose

and content of a declaration of conformity and incorporation are explained along with when to use which. The role

and process of risk assessment are explained.

The design, supply and incorporation of machinery into assemblies within the European Economic area is governed by the European Machinery Directive that was significantly amended in 2006. In the UK this directive has been transposed into the Supply of Machinery (Safety)

Regulations that came into force at the end of December 2009.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series Machinery DirectivePrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

Machinery Series - Machinery Risk Assessment EssentialsCourse Description

This training course gives delegates practical hands-on experience of conducting a machinery risk assessmentusing structured techniques which demystify the process given in BS EN ISO 12100: 2010. It assumes a basic

level of understanding of machinery safety.

The ability to carry out a detailed machinery risk assessment has, for some time, been a key skill required under the Management of Health and Safety at Work Regs. Machinery risk assessment is also now explicitly required by the Supply of Machinery (Safety) Regulations

2008. However, many people still struggle to know what is suitable and sufficient to satisfy these regulations.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8

Course Name

Machinery Series - Machinery Risk Assessment EssentialsCourse Description

This training course gives delegates practical hands-on experience of conducting a machinery risk assessmentusing structured techniques which demystify the process given in BS EN ISO 12100: 2010. It assumes a basic

level of understanding of machinery safety.

The ability to carry out a detailed machinery risk assessment has, for some time, been a key skill required under the Management of Health and Safety at Work Regs. Machinery risk assessment is also now explicitly required by the Supply of Machinery (Safety) Regulations

2008. However, many people still struggle to know what is suitable and sufficient to satisfy these regulations.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series RiskPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

Machinery Series - PUWERCourse Description

veryone who works with machinery, whether directly or indirectly, need to understand the basics of machinerysafety but not everyone needs to know all the details relating to the design. This course covers those activities

regulated by the Provision and Use of Work Equipment Regulations (PUWER) and provides delegates with a thorough knowledge of this legislation. The course will also give practical advice on how to evaluate the safety of existing machines and how to measure and evaluate noise and vibration risks.

Provision and Use of Work Equipment Regulations 1998 (PUWER) often abbreviated to PUWER, place duties on

people and companies who own, operate or have control over work equipment. PUWER also places responsibilities

on businesses and organisations whose employees use work equipment, whether owned by them or not.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8

Course Name

Machinery Series - PUWERCourse Description

veryone who works with machinery, whether directly or indirectly, need to understand the basics of machinerysafety but not everyone needs to know all the details relating to the design. This course covers those activities

regulated by the Provision and Use of Work Equipment Regulations (PUWER) and provides delegates with a thorough knowledge of this legislation. The course will also give practical advice on how to evaluate the safety of existing machines and how to measure and evaluate noise and vibration risks.

Provision and Use of Work Equipment Regulations 1998 (PUWER) often abbreviated to PUWER, place duties on

people and companies who own, operate or have control over work equipment. PUWER also places responsibilities

on businesses and organisations whose employees use work equipment, whether owned by them or not.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series PUWERPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

Person Responsible for Racking SafetyCourse Description

This one-day racking inspection training course is provided by SEMA approved racking inspectors. It covers an in-depth look at the need for rack safety inspections, how to conduct an assessment and what actions to take on completion. It references the SEMA codes of practice and industry standards and reviews current legislation.This course will:

-Enable staff to complete racking inspections to SEMA Guidelines as detailed within HSE Guidance. -Understand and perform the role of the PRRS (Person Responsible for Racking Safety).

-Essential for forklift operators to increase awareness of the need for safety in relation to racking systems.

-A certificate that is valid for three years is issued on completion of the course.

Audience

F&E Central Stores – Sandiacre F&E Depot Stores – UK wide SCO S&C Depot - Whitemoor Inventory managers Site Management MaintainersDuration:

1 Day Day(s)Class size:

8

Course Name

Person Responsible for Racking SafetyCourse Description

This one-day racking inspection training course is provided by SEMA approved racking inspectors. It covers an in-depth look at the need for rack safety inspections, how to conduct an assessment and what actions to take on completion. It references the SEMA codes of practice and industry standards and reviews current legislation.This course will:

-Enable staff to complete racking inspections to SEMA Guidelines as detailed within HSE Guidance. -Understand and perform the role of the PRRS (Person Responsible for Racking Safety).

-Essential for forklift operators to increase awareness of the need for safety in relation to racking systems.

-A certificate that is valid for three years is issued on completion of the course.

Audience

F&E Central Stores – Sandiacre F&E Depot Stores – UK wide SCO S&C Depot - Whitemoor Inventory managers Site Management MaintainersDuration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

PRRSPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

Machinery Series - Introduction to safeguarding and safety related controlsCourse Description

A control system or device is deemed to be safety related if it provides functions which significantly reduce the riskof a hazard, and in combination with other risk reduction measures, reduces the overall risk to a tolerable level, or

if it is required to function to maintain or achieve a safe state for the equipment under control (EUC).

These functions are known as the safety functions of the system or device and are the ability to prevent initiation of a hazard or detect the onset of a hazard, and to take

the necessary actions to terminate the hazardous event, achieve a safe state, or mitigate the consequences of a hazard.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series Safety ControlsPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Machinery Series - Machinery Machinery DirectiveCourse Description

This course gives delegates a thorough understanding of this legislation, as revised, as well as the key currentEuropean and International safety standards that support the Regulations. Delegates are shown how to build a

technical file and can practice assessing conformity to the essential health and safety requirements. The purpose

and content of a declaration of conformity and incorporation are explained along with when to use which. The role

and process of risk assessment are explained.

The design, supply and incorporation of machinery into assemblies within the European Economic area is governed by the European Machinery Directive that was significantly amended in 2006. In the UK this directive has been transposed into the Supply of Machinery (Safety)

Regulations that came into force at the end of December 2009.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series Machinery DirectivePrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Machinery Series - Machinery Risk Assessment EssentialsCourse Description

This training course gives delegates practical hands-on experience of conducting a machinery risk assessmentusing structured techniques which demystify the process given in BS EN ISO 12100: 2010. It assumes a basic

level of understanding of machinery safety.

The ability to carry out a detailed machinery risk assessment has, for some time, been a key skill required under the Management of Health and Safety at Work Regs. Machinery risk assessment is also now explicitly required by the Supply of Machinery (Safety) Regulations

2008. However, many people still struggle to know what is suitable and sufficient to satisfy these regulations.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series RiskPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Machinery Series - PUWERCourse Description

veryone who works with machinery, whether directly or indirectly, need to understand the basics of machinerysafety but not everyone needs to know all the details relating to the design. This course covers those activities

regulated by the Provision and Use of Work Equipment Regulations (PUWER) and provides delegates with a thorough knowledge of this legislation. The course will also give practical advice on how to evaluate the safety of existing machines and how to measure and evaluate noise and vibration risks.

Provision and Use of Work Equipment Regulations 1998 (PUWER) often abbreviated to PUWER, place duties on

people and companies who own, operate or have control over work equipment. PUWER also places responsibilities

on businesses and organisations whose employees use work equipment, whether owned by them or not.

Audience

All those in the F & E Assurance and HSE Teams. Fleet Engineering Managers, AHD/MHD Supervisors and those that interface with Plant.Duration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

Mach Series PUWERPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Person Responsible for Racking SafetyCourse Description

This one-day racking inspection training course is provided by SEMA approved racking inspectors. It covers an in-depth look at the need for rack safety inspections, how to conduct an assessment and what actions to take on completion. It references the SEMA codes of practice and industry standards and reviews current legislation.This course will:

-Enable staff to complete racking inspections to SEMA Guidelines as detailed within HSE Guidance. -Understand and perform the role of the PRRS (Person Responsible for Racking Safety).

-Essential for forklift operators to increase awareness of the need for safety in relation to racking systems.

-A certificate that is valid for three years is issued on completion of the course.

Audience

F&E Central Stores – Sandiacre F&E Depot Stores – UK wide SCO S&C Depot - Whitemoor Inventory managers Site Management MaintainersDuration:

1 Day Day(s)Class size:

8Competence Name Awarded:

Competence Awarded:

Course Code:

PRRSPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book