Course Search Results

Course Search Results

Course Name

Hot Axle Box Detector (HABD) FUES EPOS–2nd Line MaintenanceCourse Description

The aim of the course is to provide a deeper understanding of the HABD FUES-EPOS system and how to conduct corrective maintenance and run appropriate tests.Audience

This training course is designed for front line workers who are to carry out corrective and preventative maintenance on Hot Axle Box Detectors FUES-EPOS.Duration:

3 Day(s)Class size:

6

Course Name

Hot Axle Box Detector (HABD) FUES EPOS–2nd Line MaintenanceCourse Description

<p>The aim of the course is to provide a deeper understanding of the HABD FUES-EPOS system and how to conduct corrective maintenance and run appropriate tests.</p>Audience

This training course is designed for front line workers who are to carry out corrective and preventative maintenance on Hot Axle Box Detectors FUES-EPOS.Duration:

3 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.FUES EPOS CorrectiveCompetence Awarded:

Sig 22.07bCourse Code:

STF 90078Prerequisite Name:

Sig 22.07a–Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.FUES EPOS Preventative SIG MAINT TEST SMTH.a - CCS Signal Maintenance Testing Core Skills Sig 05 Undertake corrective and preventative maintenance of Track Circuits. Sig 05.04 Undertake corrective and preventative maintenance of Track Circuits.DC type Sig 07 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Sig 07.01 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.Ancillary Signals Sig 07.05 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.AWS Equipment Sig 07.09 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.TPWS Equipment Sig 07.12 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.Banner Signals Sig 13 Undertake corrective and preventative maintenance of Signalling Power Supplies. Sig 14 Undertake corrective and preventative maintenance of Signalling Cables. Sig 23 Undertake initial diagnosis of failures to determine the necessary course of action. Sig 23.01 Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Sig 24 Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Sig 25 Take and relinquish responsibility for Signalling equipment.Prerequisite Short Code:

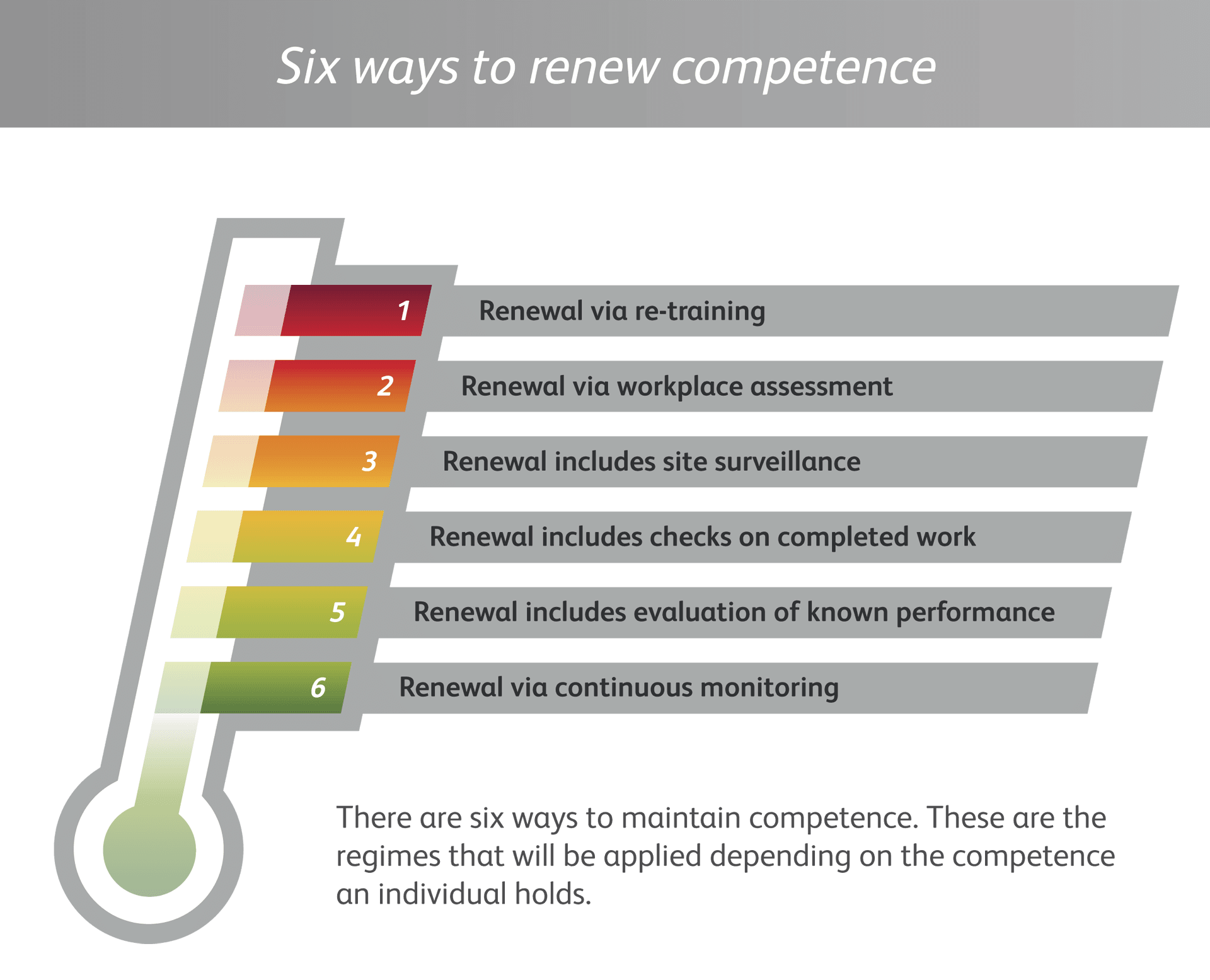

Skills Assessment Scheme Regime:

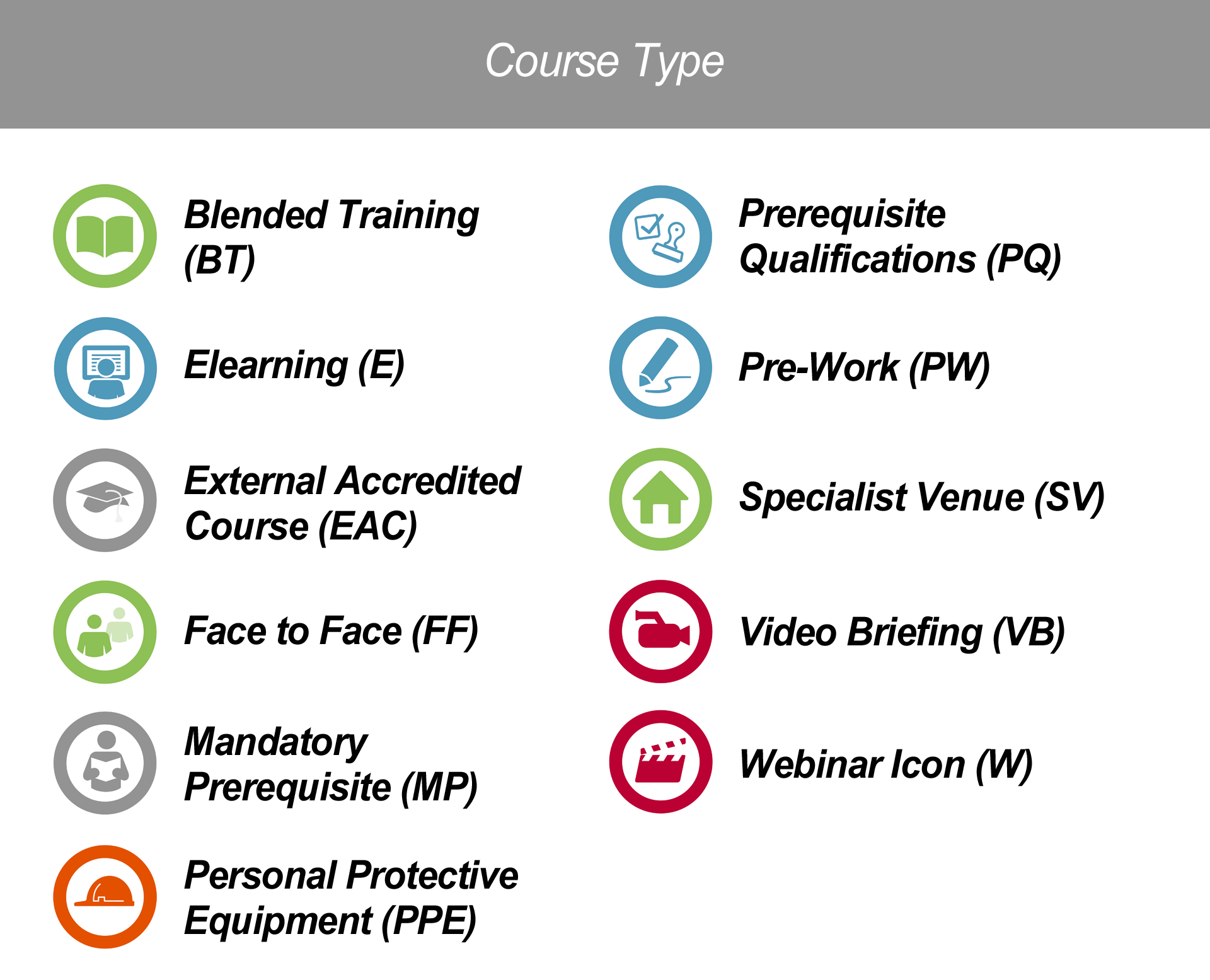

Course Type:

Course Name

Hot Axle Box Detector (HABD) FUES EPOS–2nd Line MaintenanceCourse Description

<p>The aim of the course is to provide a deeper understanding of the HABD FUES-EPOS system and how to conduct corrective maintenance and run appropriate tests.</p>Audience

This training course is designed for front line workers who are to carry out corrective and preventative maintenance on Hot Axle Box Detectors FUES-EPOS.Duration:

3 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.FUES EPOS CorrectiveCompetence Awarded:

Sig 22.07bCourse Code:

STF 90078Prerequisite Name:

Sig 22.07a–Undertake corrective and preventative maintenance of Hot Axle Box Detector Systems.FUES EPOS Preventative SIG MAINT TEST SMTH.a - CCS Signal Maintenance Testing Core Skills Sig 05 Undertake corrective and preventative maintenance of Track Circuits. Sig 05.04 Undertake corrective and preventative maintenance of Track Circuits.DC type Sig 07 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Sig 07.01 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.Ancillary Signals Sig 07.05 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.AWS Equipment Sig 07.09 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.TPWS Equipment Sig 07.12 Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS.Banner Signals Sig 13 Undertake corrective and preventative maintenance of Signalling Power Supplies. Sig 14 Undertake corrective and preventative maintenance of Signalling Cables. Sig 23 Undertake initial diagnosis of failures to determine the necessary course of action. Sig 23.01 Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Sig 24 Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Sig 25 Take and relinquish responsibility for Signalling equipment.Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book