Switches and Crossings

Switches and Crossings

Course Name

HW 1000 / 2000 PointsCourse Description

To develop the delegates understanding of maintenance, faulting repairing or testing procedures that apply to Alstom type HW points. On successful completion of the course assessments, a Statement of Achievement will be issued to the delegate.Audience

This course is designed to train persons who are responsible for the maintenance, faulting repairing or testing of the Signal Engineering equipment.Before attending this training a person should have successfully completed Point Fittings FLMF.Duration:

5 Day(s)Class size:

6

Course Name

HW 1000 / 2000 PointsCourse Description

To develop the delegates understanding of maintenance, faulting repairing or testing procedures that apply to Alstom type HW points. On successful completion of the course assessments, a Statement of Achievement will be issued to the delegate.Audience

This course is designed to train persons who are responsible for the maintenance, faulting repairing or testing of the Signal Engineering equipment.Before attending this training a person should have successfully completed Point Fittings FLMF.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HW 1000 / 2000 PointsCompetence Awarded:

SIG MAINT POINTS 01.304Course Code:

STF 061Prerequisite Name:

Prerequisite Short Code:

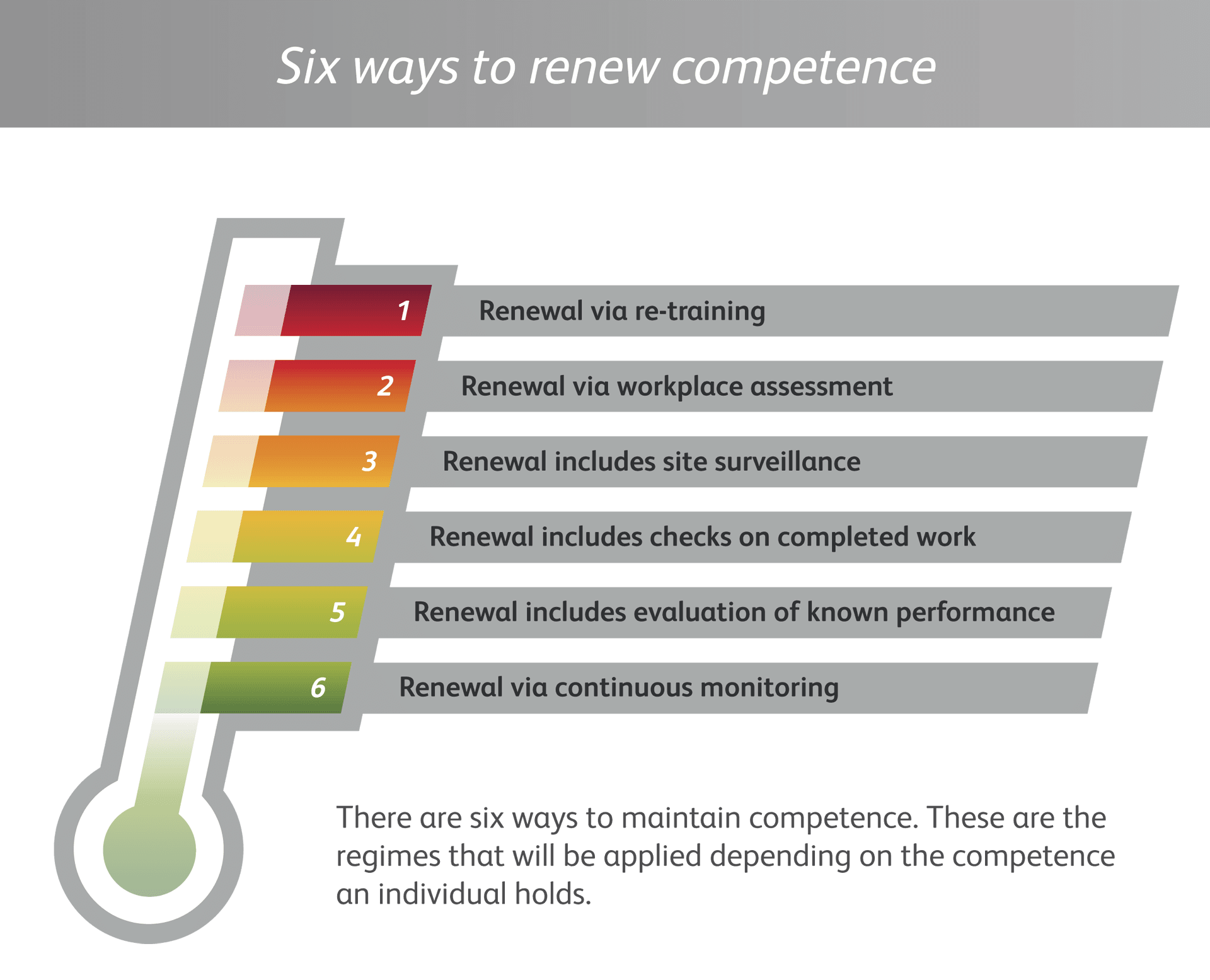

Skills Assessment Scheme Regime:

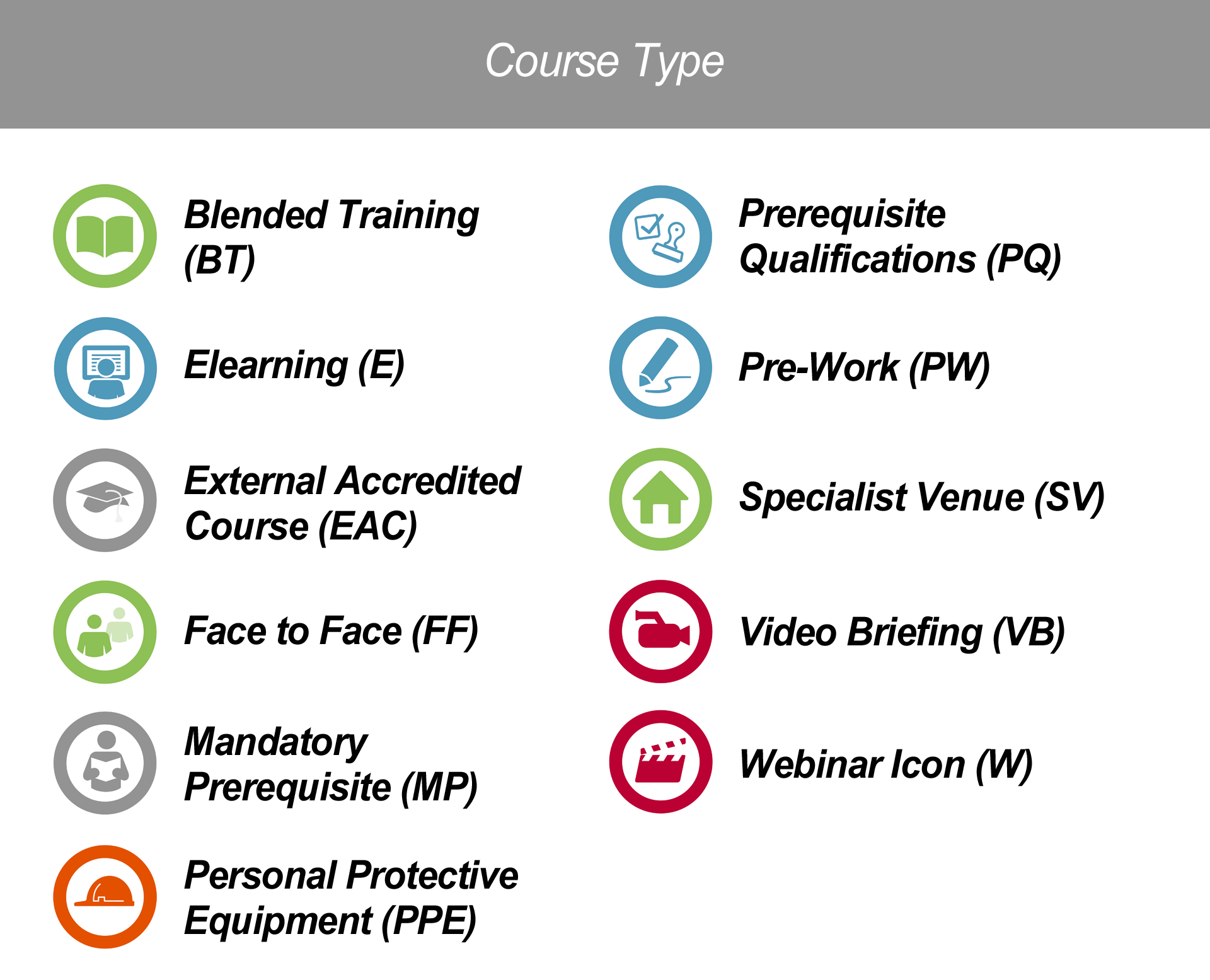

3Course Type:

Course Name

Hy-Drive ConversionCourse Description

At the end of this training event, delegates will understand and/or be able to: Identification of system components. Perform signalling maintenance to the required specifications. Find and repair faults in line with themanufacturers operation.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the installation, Faulting or maintenance of the Hy-drive points system.Duration:

3 Day(s)Class size:

4

Course Name

Hy-Drive ConversionCourse Description

At the end of this training event, delegates will understand and/or be able to: Identification of system components. Perform signalling maintenance to the required specifications. Find and repair faults in line with themanufacturers operation.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the installation, Faulting or maintenance of the Hy-drive points system.Duration:

3 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks.In Bearer Undertake corrective and preventative maintenance of Rail Clamp Point Locks.SO Backdrives Install and adjust Rail Clamp Point Locks.In Bearer InstallationCompetence Awarded:

Sig 12.01; Sig 12.03; Sig 34.01Course Code:

STF 084Prerequisite Name:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks.Rail Mounted OR Install and adjust Rail Clamp Point Locks.Rail Mounted InstallationPrerequisite Short Code:

Sig 12.02; Sig 34.02Skills Assessment Scheme Regime:

3&4Course Type:

Course Name

IBCL ConversionCourse Description

This module is designed for people who are responsible for undertaking In Bearer Clamp Lock maintenance, installation and faulting as part of their duties on NR Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the Installation, maintenance or faulting of the IBCL points system.. Attendees for this event should already be competent in RCPL's(Rail Clamp Point Lock) and this is a 2 day event to convert from an RCPL competency. If no previous clam plock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead.Duration:

2 Day(s)Class size:

4

Course Name

IBCL ConversionCourse Description

This module is designed for people who are responsible for undertaking In Bearer Clamp Lock maintenance, installation and faulting as part of their duties on NR Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the Installation, maintenance or faulting of the IBCL points system.. Attendees for this event should already be competent in RCPL's(Rail Clamp Point Lock) and this is a 2 day event to convert from an RCPL competency. If no previous clam plock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead.Duration:

2 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks; Install and adjust Rail Clamp Point Locks; Undertake corrective and preventative maintenance of Rail Clamp Point LocksCompetence Awarded:

Sig 12; Sig 34.01; Sig 12.01Course Code:

STF 083Prerequisite Name:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks. Rail Mounted OR Install and adjust Rail Clamp Point Locks. Rail Mounted InstallationPrerequisite Short Code:

Sig 12.02 OR Sig 34.02Skills Assessment Scheme Regime:

Course Type:

Course Name

Points FittingsCourse Description

Develops understanding of the maintenance, faulting, repairing and testing procedures that apply to point fittings, fixed stretcher bars, adjustable stretcher bars, supplementary drives and detectors.Audience

Anyone responsible for the maintenance, faulting, repairing or testing of point fittings, fixed and adjustable stretcher bars, supplementatry drives and detectors signal engineering equipment.Duration:

4 Day(s)Class size:

6

Course Name

Points FittingsCourse Description

Develops understanding of the maintenance, faulting, repairing and testing procedures that apply to point fittings, fixed stretcher bars, adjustable stretcher bars, supplementary drives and detectors.Audience

Anyone responsible for the maintenance, faulting, repairing or testing of point fittings, fixed and adjustable stretcher bars, supplementatry drives and detectors signal engineering equipment.Duration:

4 Day(s)Class size:

6Competence Name Awarded:

Undertake Corrective and Preventative Maintenance of Points Fittings; Undertake Corrective and Preventative Maintenance of Points Fittings.Points FittingsCompetence Awarded:

Sig 39; Sig 39.01Course Code:

STF 060Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits; Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS; Undertake corrective and preventative maintenance of Signalling Power Supplies; Undertake corrective and preventative maintenance of Signalling Cables; Signal Maintenance Testing.Core Skills Take and relinquish responsibility for Signalling equipment; Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activitiesPrerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

3Course Type:

Course Name

Points HPSS FLMFCourse Description

Provides knowledge and skills to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out preventative maintenance procedures and tests; complete recording and reporting documentation.Audience

Anyone responsible for the maintenance, faulting repairing or testing of this system and who has at least 6 months workplace experience.Duration:

5 Day(s)Class size:

6

Course Name

Points HPSS FLMFCourse Description

Provides knowledge and skills to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out preventative maintenance procedures and tests; complete recording and reporting documentation.Audience

Anyone responsible for the maintenance, faulting repairing or testing of this system and who has at least 6 months workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HPSS Points (Incl Power Link)Competence Awarded:

SIG MAINT POINTS 01.306Course Code:

STF 70Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

Course Name

Points HW InstallationCourse Description

Provides an understanding of installation, adjustment and testing procedures that apply to HW Point Machines.Audience

Anyone responsible for installation, adjustment or testing of the Signal Engineering equipment.Duration:

4 Day(s)Class size:

6

Course Name

Points HW InstallationCourse Description

Provides an understanding of installation, adjustment and testing procedures that apply to HW Point Machines.Audience

Anyone responsible for installation, adjustment or testing of the Signal Engineering equipment.Duration:

4 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HW 1000 / 2000 PointsCompetence Awarded:

SIG MAINT POINTS 01.304Course Code:

STF 062Prerequisite Name:

Undertake Corrective and Preventative Maintenance of Points Fittings; Undertake Corrective and Preventative Maintenance of Points Fittings.Points FittingsPrerequisite Short Code:

Skills Assessment Scheme Regime:

4Course Type:

Course Name

Points Style 63 FLMFCourse Description

Provides knowledge and skills to be able to maintain, repair, adjust and test Style 63 Clamp Locks.Audience

Anyone responsible for maintenance, adjustment or testing of the Signal Engineering equipment, have the required competences and not less than 12 months work experience in a signal maintenance, faulting, installation or testing environment.Duration:

5 Day(s)Class size:

6

Course Name

Points Style 63 FLMFCourse Description

Provides knowledge and skills to be able to maintain, repair, adjust and test Style 63 Clamp Locks.Audience

Anyone responsible for maintenance, adjustment or testing of the Signal Engineering equipment, have the required competences and not less than 12 months work experience in a signal maintenance, faulting, installation or testing environment.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; M63 Points.Competence Awarded:

SIG MAINT POINTS 01.303Course Code:

STF 068Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

Course Name

RCPL / IBCL - Installation, Faulting and MaintenanceCourse Description

This module is designed to train persons who are responsible for undertaking Rail Clamp Point Lock or In Bearer Clamp Lock maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation or Faulting where equipment is installed. Signalling grades whose work involves the installation / maintenance of the RCPL or IBCL points system.. Attendees for this event should be new to Clamplocks. If IBCL is required and RCPL is already held then STFxx IBCL conversion or STFxx HY-Drive Conversion should be considered.Duration:

5 Day(s)Class size:

6

Course Name

RCPL / IBCL - Installation, Faulting and MaintenanceCourse Description

This module is designed to train persons who are responsible for undertaking Rail Clamp Point Lock or In Bearer Clamp Lock maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation or Faulting where equipment is installed. Signalling grades whose work involves the installation / maintenance of the RCPL or IBCL points system.. Attendees for this event should be new to Clamplocks. If IBCL is required and RCPL is already held then STFxx IBCL conversion or STFxx HY-Drive Conversion should be considered.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; IBCL/RCPL Points (Mk 1 and 2)Competence Awarded:

SIG MAINT POINTS 01.401Course Code:

STF 081Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

SO Supplementary DriveCourse Description

This module is designed to train persons who are responsible for undertaking SO Supplementary Drive maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation and Faulting where equipment is installed. Signalling maintenance grades whose work involves the maintenance, Installation or Faulting of the SO Supplementary drive system.. Attendees for this event should already be competent in IBCL's (In-Bearer Clamplock) and this is a 1 day event to convert from an IBCL competency. If no previous Clamplock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead before attendance of the 1 day SO event. If RCPL held and IBCL not held then the HY-Drive conversion event (3days STFxx) should be considered.Duration:

1 Day(s)Class size:

4

Course Name

SO Supplementary DriveCourse Description

This module is designed to train persons who are responsible for undertaking SO Supplementary Drive maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation and Faulting where equipment is installed. Signalling maintenance grades whose work involves the maintenance, Installation or Faulting of the SO Supplementary drive system.. Attendees for this event should already be competent in IBCL's (In-Bearer Clamplock) and this is a 1 day event to convert from an IBCL competency. If no previous Clamplock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead before attendance of the 1 day SO event. If RCPL held and IBCL not held then the HY-Drive conversion event (3days STFxx) should be considered.Duration:

1 Day(s)Class size:

4Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; SO Supplementary DriveCompetence Awarded:

SIG MAINT POINTS 01.102Course Code:

STF 082Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

Course Name

Tubular Stretcher BarCourse Description

Provides skills and knowledge to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out maintenance, installation and adjustment procedures and tests for the equipment; complete recording and reporting documentation.Audience

Anyone who is competent in sig 39.01 and responsible for carrying out routine installation, maintenance and test of the tubular stretcher bar.Duration:

1 Day(s)Class size:

6

Course Name

Tubular Stretcher BarCourse Description

Provides skills and knowledge to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out maintenance, installation and adjustment procedures and tests for the equipment; complete recording and reporting documentation.Audience

Anyone who is competent in sig 39.01 and responsible for carrying out routine installation, maintenance and test of the tubular stretcher bar.Duration:

1 Day(s)Class size:

6Competence Name Awarded:

Install and Maintain Tubular Stretcher Bar.Competence Awarded:

Sig 58Course Code:

STF 066Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

5Course Type:

Course Name

HW 1000 / 2000 PointsCourse Description

To develop the delegates understanding of maintenance, faulting repairing or testing procedures that apply to Alstom type HW points. On successful completion of the course assessments, a Statement of Achievement will be issued to the delegate.Audience

This course is designed to train persons who are responsible for the maintenance, faulting repairing or testing of the Signal Engineering equipment.Before attending this training a person should have successfully completed Point Fittings FLMF.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HW 1000 / 2000 PointsCompetence Awarded:

SIG MAINT POINTS 01.304Course Code:

STF 061Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

How to Book

Course Name

Hy-Drive ConversionCourse Description

At the end of this training event, delegates will understand and/or be able to: Identification of system components. Perform signalling maintenance to the required specifications. Find and repair faults in line with themanufacturers operation.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the installation, Faulting or maintenance of the Hy-drive points system.Duration:

3 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks.In Bearer Undertake corrective and preventative maintenance of Rail Clamp Point Locks.SO Backdrives Install and adjust Rail Clamp Point Locks.In Bearer InstallationCompetence Awarded:

Sig 12.01; Sig 12.03; Sig 34.01Course Code:

STF 084Prerequisite Name:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks.Rail Mounted OR Install and adjust Rail Clamp Point Locks.Rail Mounted InstallationPrerequisite Short Code:

Sig 12.02; Sig 34.02Skills Assessment Scheme Regime:

3&4Course Type:

How to Book

Course Name

IBCL ConversionCourse Description

This module is designed for people who are responsible for undertaking In Bearer Clamp Lock maintenance, installation and faulting as part of their duties on NR Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance where equipment is installed. Signalling grades whose work involves the Installation, maintenance or faulting of the IBCL points system.. Attendees for this event should already be competent in RCPL's(Rail Clamp Point Lock) and this is a 2 day event to convert from an RCPL competency. If no previous clam plock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead.Duration:

2 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks; Install and adjust Rail Clamp Point Locks; Undertake corrective and preventative maintenance of Rail Clamp Point LocksCompetence Awarded:

Sig 12; Sig 34.01; Sig 12.01Course Code:

STF 083Prerequisite Name:

Undertake corrective and preventative maintenance of Rail Clamp Point Locks. Rail Mounted OR Install and adjust Rail Clamp Point Locks. Rail Mounted InstallationPrerequisite Short Code:

Sig 12.02 OR Sig 34.02Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Points FittingsCourse Description

Develops understanding of the maintenance, faulting, repairing and testing procedures that apply to point fittings, fixed stretcher bars, adjustable stretcher bars, supplementary drives and detectors.Audience

Anyone responsible for the maintenance, faulting, repairing or testing of point fittings, fixed and adjustable stretcher bars, supplementatry drives and detectors signal engineering equipment.Duration:

4 Day(s)Class size:

6Competence Name Awarded:

Undertake Corrective and Preventative Maintenance of Points Fittings; Undertake Corrective and Preventative Maintenance of Points Fittings.Points FittingsCompetence Awarded:

Sig 39; Sig 39.01Course Code:

STF 060Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits; Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS; Undertake corrective and preventative maintenance of Signalling Power Supplies; Undertake corrective and preventative maintenance of Signalling Cables; Signal Maintenance Testing.Core Skills Take and relinquish responsibility for Signalling equipment; Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activitiesPrerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

3Course Type:

How to Book

Course Name

Points HPSS FLMFCourse Description

Provides knowledge and skills to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out preventative maintenance procedures and tests; complete recording and reporting documentation.Audience

Anyone responsible for the maintenance, faulting repairing or testing of this system and who has at least 6 months workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HPSS Points (Incl Power Link)Competence Awarded:

SIG MAINT POINTS 01.306Course Code:

STF 70Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

How to Book

Course Name

Points HW InstallationCourse Description

Provides an understanding of installation, adjustment and testing procedures that apply to HW Point Machines.Audience

Anyone responsible for installation, adjustment or testing of the Signal Engineering equipment.Duration:

4 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; HW 1000 / 2000 PointsCompetence Awarded:

SIG MAINT POINTS 01.304Course Code:

STF 062Prerequisite Name:

Undertake Corrective and Preventative Maintenance of Points Fittings; Undertake Corrective and Preventative Maintenance of Points Fittings.Points FittingsPrerequisite Short Code:

Skills Assessment Scheme Regime:

4Course Type:

How to Book

Course Name

Points Style 63 FLMFCourse Description

Provides knowledge and skills to be able to maintain, repair, adjust and test Style 63 Clamp Locks.Audience

Anyone responsible for maintenance, adjustment or testing of the Signal Engineering equipment, have the required competences and not less than 12 months work experience in a signal maintenance, faulting, installation or testing environment.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; M63 Points.Competence Awarded:

SIG MAINT POINTS 01.303Course Code:

STF 068Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

How to Book

Course Name

RCPL / IBCL - Installation, Faulting and MaintenanceCourse Description

This module is designed to train persons who are responsible for undertaking Rail Clamp Point Lock or In Bearer Clamp Lock maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation or Faulting where equipment is installed. Signalling grades whose work involves the installation / maintenance of the RCPL or IBCL points system.. Attendees for this event should be new to Clamplocks. If IBCL is required and RCPL is already held then STFxx IBCL conversion or STFxx HY-Drive Conversion should be considered.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; IBCL/RCPL Points (Mk 1 and 2)Competence Awarded:

SIG MAINT POINTS 01.401Course Code:

STF 081Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

SO Supplementary DriveCourse Description

This module is designed to train persons who are responsible for undertaking SO Supplementary Drive maintenance and faulting activities as part of their duties on Network Rail Infrastructure.Audience

Personnel who are responsible for: Routine signalling maintenance, Installation and Faulting where equipment is installed. Signalling maintenance grades whose work involves the maintenance, Installation or Faulting of the SO Supplementary drive system.. Attendees for this event should already be competent in IBCL's (In-Bearer Clamplock) and this is a 1 day event to convert from an IBCL competency. If no previous Clamplock competencies held then STF xx Full RCPL / IBCL event 5 days should be attended instead before attendance of the 1 day SO event. If RCPL held and IBCL not held then the HY-Drive conversion event (3days STFxx) should be considered.Duration:

1 Day(s)Class size:

4Competence Name Awarded:

CCS Install, Setup and Maintain Point Equipment; SO Supplementary DriveCompetence Awarded:

SIG MAINT POINTS 01.102Course Code:

STF 082Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

3Course Type:

How to Book

Course Name

Tubular Stretcher BarCourse Description

Provides skills and knowledge to be able to identify what each of the component parts being installed contributes to the overall operation of the system; describe what your role and responsibilities and authorities are; carry out maintenance, installation and adjustment procedures and tests for the equipment; complete recording and reporting documentation.Audience

Anyone who is competent in sig 39.01 and responsible for carrying out routine installation, maintenance and test of the tubular stretcher bar.Duration:

1 Day(s)Class size:

6Competence Name Awarded:

Install and Maintain Tubular Stretcher Bar.Competence Awarded:

Sig 58Course Code:

STF 066Prerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

5Course Type:

How to Book